Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The sanitary Aseptic TC sampling valve is a specialized valve designed for accurate and hygienic sampling of fluids in sanitary systems. It provides a reliable and efficient solution for obtaining representative samples in various industries.

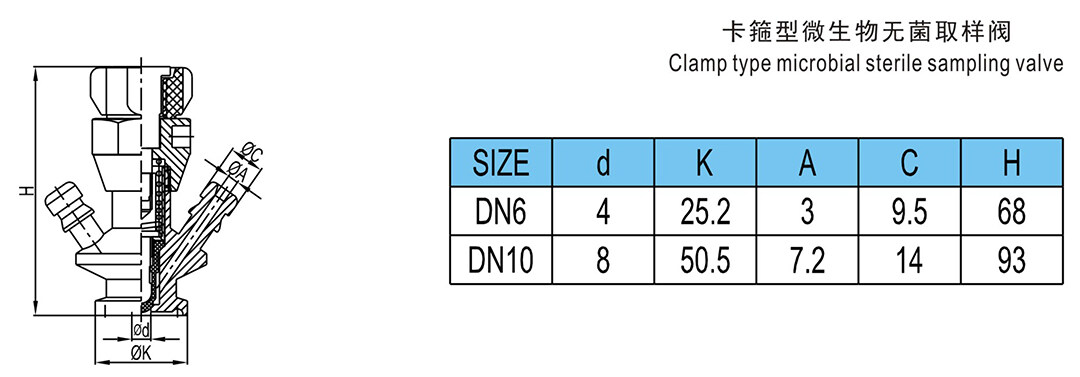

Product parameter

| Standard | SMS,DIN,3A | |

| Material Contact Parts | SS316L(1.4404) | Provided with material inspection report |

| Size | DN6,DN10,DN15 | |

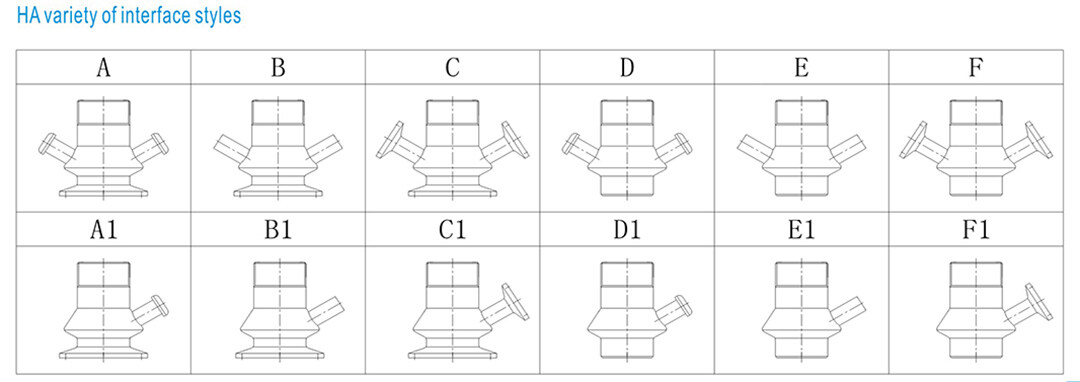

| Body Combination |

A Model,B Model,C Model,D Model,E Model,F Model A1 Model,B1 Model, C1 Model,D1 Model,E1 Model, F1Model |

|

| Connection | Butt-weld,Tri-clamp | |

| Seal Material | Silicone Seal. The seal material comply with FDA21CFR117.2600 | |

| Power Option | Manual Operated | |

| Working Pressure | ≤10bar(145psi) | |

| Supply Pressure for Air Actuator | 5~8(72.52psi~116psi) | |

| External Surface Treatment | Ra16~32uin(0.4~0.8um) | |

| Internal Surface Treatment | Ra16~32uin(0.4~0.8um) | |

The sanitary sampling valve is specifically designed for the purpose of sampling fluids in sanitary systems. It features a compact and ergonomic design, allowing for easy installation and operation. The valve is equipped with a sampling port that enables controlled and representative sampling of fluids without compromising the integrity of the system.

Product drawing

Product Features

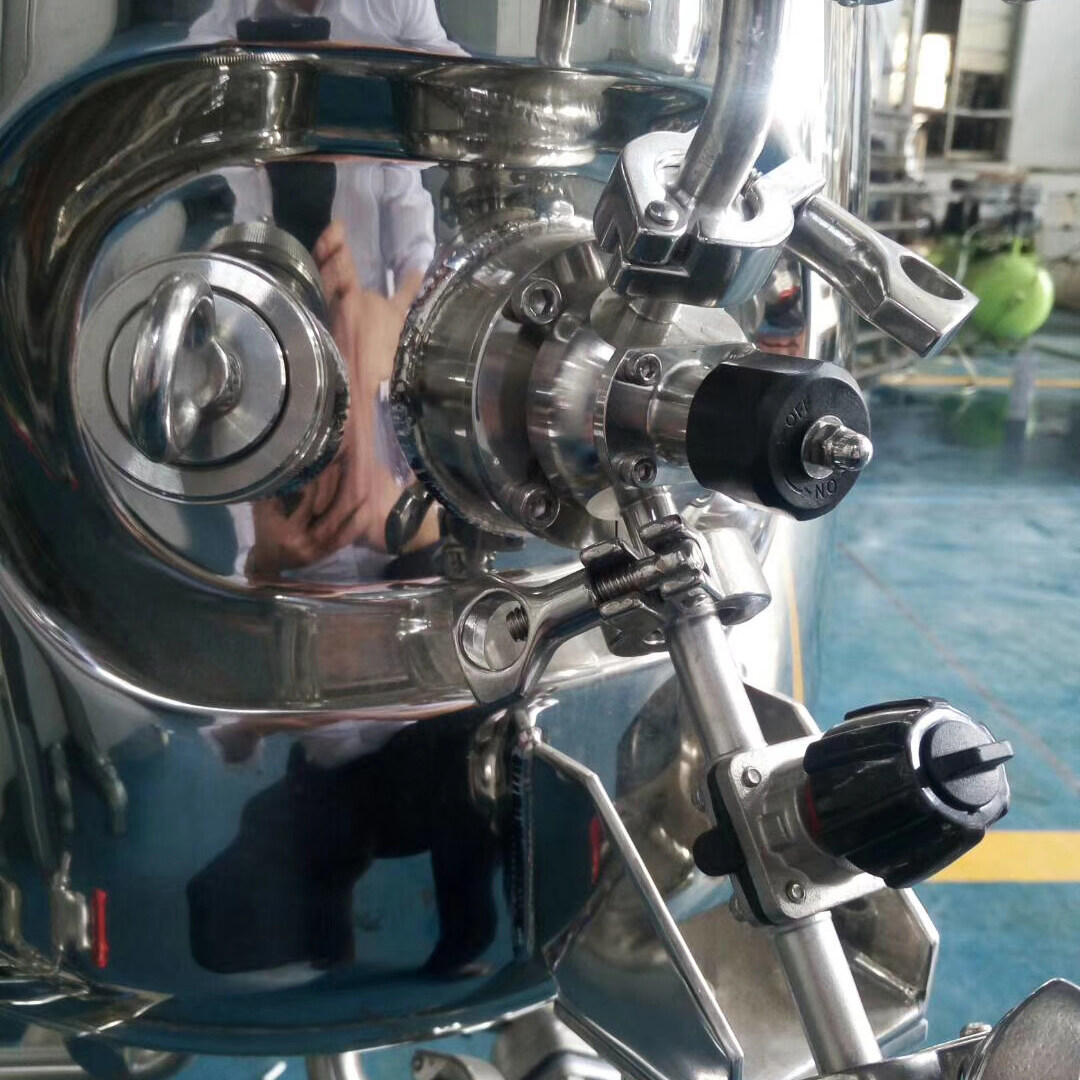

Application scenario

Product Advantages

1.Accurate Sampling: The sanitary sampling valve ensures accurate and representative sampling, providing reliable data for analysis and quality control. The valve’s precise control over the flow rate and volume of the sampled fluid ensures that the collected sample is a true representation of the bulk fluid.

2.Hygienic Sampling Process: The sampling valve’s hygienic design is specifically engineered to prevent contamination during the sampling process. The use of sanitary materials and smooth, crevice-free surfaces minimizes the risk of microbial growth, cross-contamination, and product degradation. This feature ensures the integrity and purity of the sampled fluids, making the valve suitable for applications in sensitive industries such as food, pharmaceuticals, and biotechnology.

3.Time and Cost Savings: The precise control and efficiency of the sampling valve result in significant time and cost savings. The valve allows for quick and controlled sampling, reducing the time required for sample collection. Its accurate sampling capabilities eliminate the need for repeated sampling, minimizing material and labor costs.